In the intricate network of pipelines and water distribution systems, sluice valves stand as silent sentinels, regulating the flow of fluids with precision and reliability. These essential components play a pivotal role in controlling the movement of water in various applications, from municipal water distribution to industrial processes. In this blog post, we delve into the inner workings, benefits, and applications of sluice valves, shedding light on their importance in modern engineering and infrastructure.

Understanding Sluice Valves

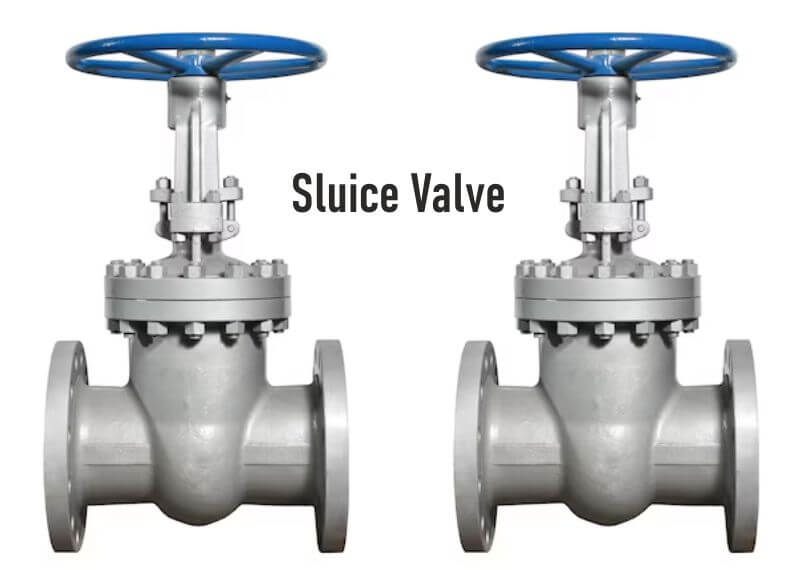

Sluice valves, also known as gate valves, are devices designed to control the flow of fluids by opening, closing, or partially obstructing the passage within a pipeline. They consist of a gate or wedge-shaped disk that moves perpendicular to the direction of flow to regulate the flow rate. The actuation mechanism typically involves a threaded stem or handwheel that raises or lowers the gate to adjust the flow.

Mechanisms and Components Gate: The gate is the central component of the sluice valve, serving as the barrier that either allows or obstructs the flow of fluid. It is typically made of materials such as cast iron, ductile iron, or stainless steel, chosen for their strength and corrosion resistance.

Stem and Handwheel: The stem connects the gate to the actuation mechanism, allowing for manual operation. It extends through the valve body and is connected to a handwheel or operating nut, which facilitates the opening and closing of the valve.

Valve Body: The valve body houses the gate and stem, providing support and alignment. It is designed to withstand the pressure and forces exerted by the fluid flowing through the pipeline.

Sealing Mechanism: Sluice valves employ various sealing mechanisms to prevent leakage when the valve is closed. This may include resilient seat rings, O-rings, or metal-to-metal contact between the gate and valve body.

Advantages and Benefits

Precise Flow Control: Sluice valves offer precise control over the flow rate, allowing operators to regulate the volume of fluid passing through the pipeline with accuracy.

Low Pressure Drop: When fully open, sluice valves present minimal obstruction to the flow, resulting in low pressure drop across the valve and efficient fluid conveyance.

Reliable Shut-Off: Sluice valves provide reliable shut-off capabilities, effectively sealing the pipeline to prevent leakage and unauthorized flow.

Versatility: Sluice valves are versatile and can be used in a wide range of applications, including water distribution, wastewater management, irrigation, and industrial processes.

Durability: Constructed from robust materials and designed for longevity, sluice valves exhibit excellent durability and resistance to wear and corrosion, ensuring long-term performance in demanding environments.

Applications

Water Distribution: Sluice valves are widely used in municipal water distribution systems to regulate the flow of potable water to residential, commercial, and industrial consumers.

Wastewater Management: In wastewater treatment plants and sewage collection networks, sluice valves control the flow of sewage and effluent, facilitating the treatment process and preventing backflow.

Industrial Processes: Sluice valves play a crucial role in various industrial applications, including chemical processing, power generation, and mining, where they regulate the flow of fluids and control process parameters.

Fire Protection Systems: Sluice valves are integral components of fire protection systems, controlling the flow of water to sprinkler systems and fire hydrants in buildings and industrial facilities.